WATER

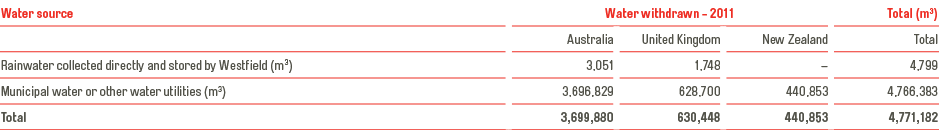

Consistent with the Group’s commitment to operate a transparent, resource-efficient business, Westfield has begun reporting externally on its water consumption across its portfolio in Australia, New Zealand and the United Kingdom.

Water Reduction Initiatives

Westfield has a number of specific water reduction initiatives underway at its centres around the world.

Just one example in Australia is the work that has been done as part of the portfolio’s Water Efficiency Plan, encouraging centres to address water wastage through environmental management initiatives.

Westfield West Lakes introduced a program to replace the use of conventional wok stoves with waterless woks in its food court retailers, after recognising the intensive water requirements of woks in the preparation of Asian-style food. Working with the local water authority, management at West Lakes was able to determine through sub-metering and data logging that an estimated 4000 litres of water per wok was used every day in the two Asian-style restaurants in the food court. This meant around 32,000 litres of water used daily for cooling and cleaning the conventional woks, representing an annual per wok cost of $5,583 when taking into consideration water supply, sewer use and trade waste charges.

The centre team worked closely with the retailers to understand their water consumption and communicate the benefits of using waterless woks. The flow rate reduced from 12 litres to less than 4 litres per minute, and manually operated valves also ensured greater control over the levels of water released. Based on the reduced water requirements and usage, estimate annual savings achieved over 2011 were calculated at approximately $15,000.

At Westfield Doncaster, also in Australia, a water audit was conducted on specialty stores, leading to the repair of identified leaks and the installation of flow rate restrictors in certain tenancies. General facility maintenance revealed a leak in the grey water tank which resulted in the rebuilding of the pump with new seals, with the $1900 required for these two actions resulting in a $15,900 annual saving (based on the water wastage costs).